SCADA/HMI

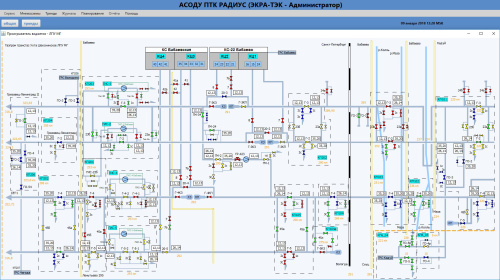

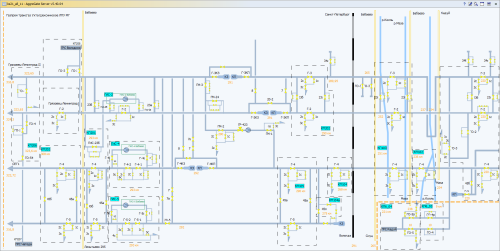

Visualize and operate the processes, production flows, machines, and plants with AggreGate SCADA/HMI – a highly reliable multi-tenant distributed solution which provides supervisory control and monitoring for all industrial sectors.

Simplify the creation of Human-Machine Interfaces with a cross-platform UI Builder application. Leverage the SCADA core and HMIs running on regular servers, industrial PCs, touch panels, Linux PLCs, IIoT gateways, and single-board computers.

Full Stack Industry 4.0

SCADA/HMI inherits the advanced data acquisition and processing capabilities

from the underlying AggreGate IIoT Platform.

Flexible and Endurant

Tested by many mission-critical cases in oil and gas, chemical and power engineering industries, AggreGate SCADA easily copes with the automotive, semiconductor, food and beverage, packaging, and other lightweight applications.

4th Generation SCADA

Cloud-friendly, web-based, secure, and cross-platform. Interoperable via standard protocols.

Leveraging scalable NoSQL databases. Offering a digital twin modeling framework.

You get everything that you expect from the IIoT-world SCADA software.

Based on IIoT Platform

Our SCADA/HMI is built atop of a mature and powerful AggreGate IoT Integration Platform. It inherits all technological benefits of the underlying framework, including open-source APIs, failover clustering, distributed architecture, process modeling, advanced analytics, and more.

Innovative Technology

The AggreGate Platform's patented technology introduces many innovations to the industrial automation domain. AggreGate's system core enables the home-grown device data normalization method, two-way device synchronization, device data caching, and other device management features.

Linux SCADA

A full-fledged AggreGate SCADA runs on Linux and Mac OS, including Linux PLCs, IoT gateways, touch panels, and single-board PCs. All features are available, including communications with the Windows-based OPC servers via a network using DCOM technology.

Unlimited Scalability

Up to 10 million tags, up to a million processed samples per second and hundreds of thousands ones stored. These are practical limits of a single server which can be endlessly expanded by the distributed architecture.

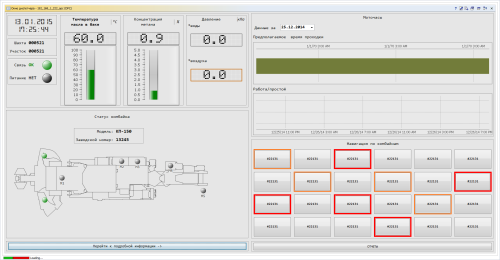

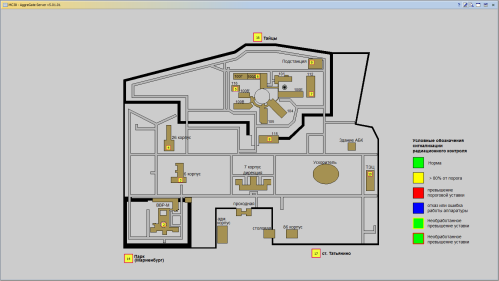

Alarming and Event Management

Advanced alerting with a deadband support. Event correlation and value flapping detection. Alert acknowledgment and escalation rules. E-mail, SMS, popup, sound, and other notifications. Automatic and interactive corrective actions.

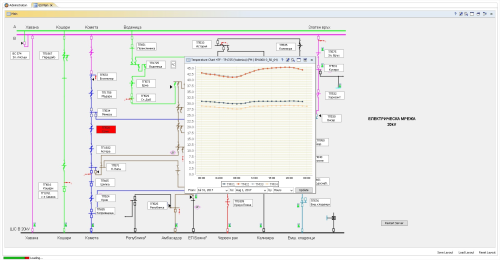

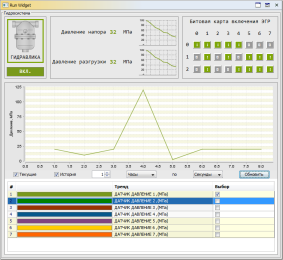

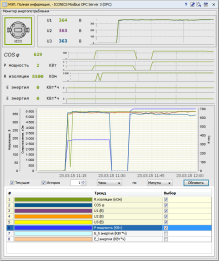

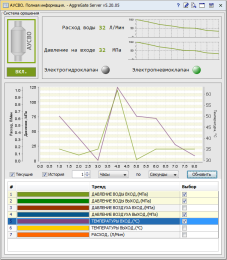

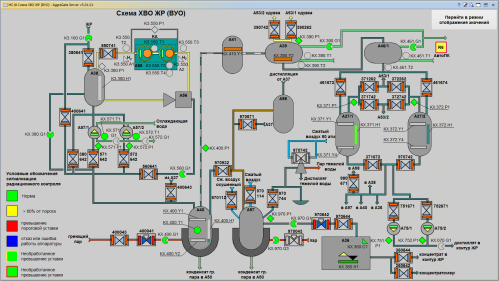

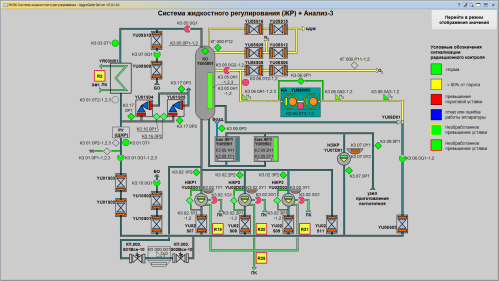

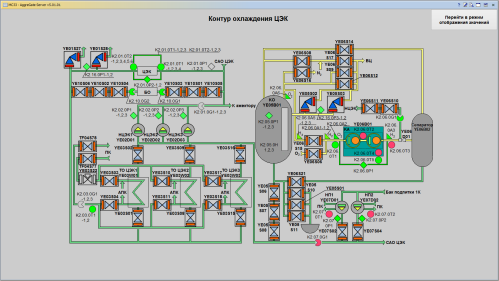

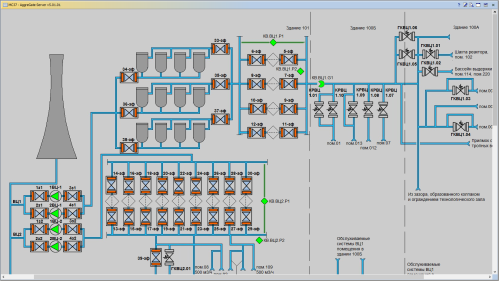

Visual HMI Builder

Integrated UI Builder supports combining the grid and absolute layouts inside different containers, allowing building very complex process control interfaces. More than 50 component types are supported, including maps, graphs, dynamic SVG images, video windows, and more.

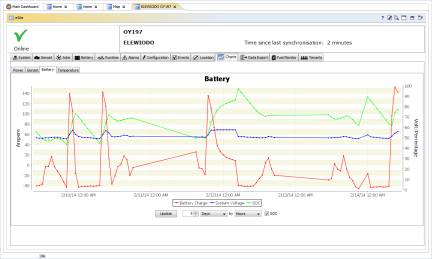

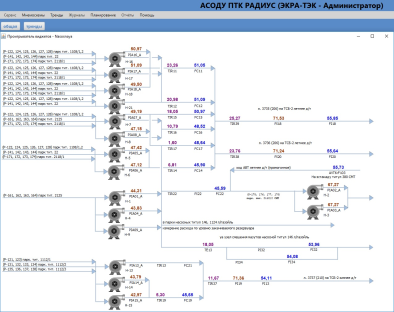

Charting and Trending

More than 25 time series and statistical diagram types. Thousands of configurable parameters for axes, series renderers, range and domain markers, legends, titles, gridlines, crosshairs, annotations, tooltips, and more. The trend options include linear, exponential, moving average or percentile.

Statistical Process Control

AggreGate can store the long-term time series data in a round-robin database (RRD), providing an extremely compact storage and fast access to historical values. Statistical process control enables deep data analysis, such as triggering an alert when a daily channel average significantly exceeds its yearly average.

Live Project Editing

Unlike traditional SCADAs, AggreGate has no difference between development and runtime environments. Remote development and administration on a production server work via the secure network connections. Device models, change history tracking, database backups, and optional failover servers keep the operations safe.

Scripting and Querying

Despite the system is tailored for visual operations, it has a strong support for the server-side and HMI-side scripting in Java, Python, R or IEC 61131-3 languages. The platform also offers two domain-specific languages: a query language for data mining and an expression language for building the alert triggers, event filters, etc.

Task Scheduler

All system actions supporting unattended mode can be executed according to a simple or advanced schedule. The simple schedule ensures that the job is executed every N seconds, while the advanced schedule allows a fine-grained planning, such as "Every 3rd Friday of May, at 11.30 pm, during the years 2018-2025".

Reporting

Any type of license allows creating an unlimited number of reports. The report source data can be extracted by an expression or query, but the report template generator can create a report template from any tabular data in just two clicks. Moreover, the templates can be fine-tuned or created from scratch in the embedded report editor.

SQL Support

AggreGate SCADA/HMI can store the configuration and value history in a standard relational database to ensure the uniform data access. Most enterprise-grade databases are supported, including MySQL, Microsoft SQL Server, Oracle, PostgreSQL, and others. The trend data storage is fully configurable in terms of sampling periods and storage duration.

SCADA Symbol Library

The SCADA installation bundle includes a huge library of dynamic automation symbols in a Scalable Vector Graphics (SVG) format. The library is divided into multiple categories like tanks, valves or pipes. All symbols support on-the-fly manipulations, such as changing colors/strokes, zoom and rotation, starting/stopping animations, and manipulating individual elements (e.g., tank levels).

Open-Source SDK

AggreGate Server provides the open-source APIs for Java, .NET, C++, JavaScript, and mobile platforms. These APIs allow a full remote control of the server and access to all server/device data from any third-party application. It's also possible to create new device drivers and data processing/presentation plugins. In addition, the AggreGate Server can be controlled via REST and SOAP web services.

Flexible Security Model

The underlying platform establishes a serious security infrastructure for AggreGate SCADA/HMI by providing a flexible role-based access control. In addition, all communications between the server, operator workstations, HMIs, and third-party systems are performed via SSL-secured connections.

PLC Languages

AggreGate SCADA can run the algorithms implemented in IEC 61131-3 languages, including the Ladder Diagram (LD), Function Block Diagram (FBD), Sequential Function Chart (SFC), and Structured Text (ST). Development and debugging using the visual languages is performed in the integrated UI builder.

Web SCADA

Every HMI designed in the AggreGate's UI builder can run in any web browser. There's no difference which UI will be used by system operators: a pixel-level compatibility is guaranteed between the unified console application and the web interface.

Your Value-Adding Catch

AggreGate is initially designed for ensuring the flexibility and independence of our certified partners:

- Taken aboard by hundreds of system integration and engineering companies worldwide

- Renders the cloud-based automation services provided by MSPs

- Rebranded and redistributed by OEM vendors of PLCs and IIoT gateways

We were impressed by the AggreGate’s capabilities. We had to spend a lot of time when getting used to the product, but your elaborate and well-described documentation helped us a lot. Not to mention your timely response helped us complete the job in time.

What else do the customers say about AggreGate? View all testimonials

Worldwide Expertise

Thousands of process control systems on all continents are supervised by AggreGate. Check some references below or jump to the detailed reference list.

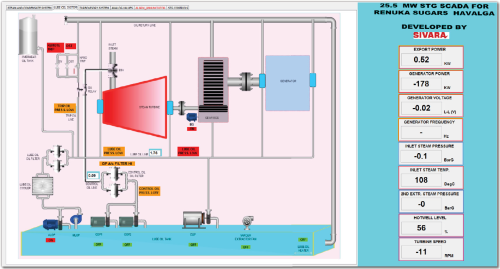

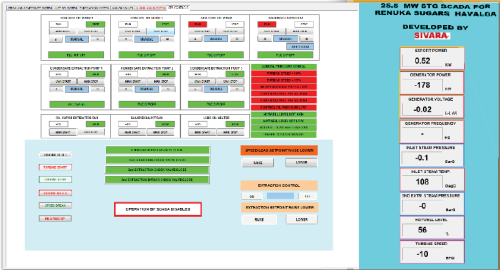

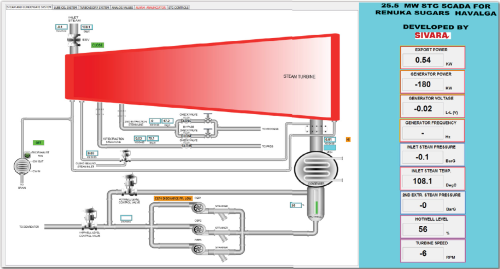

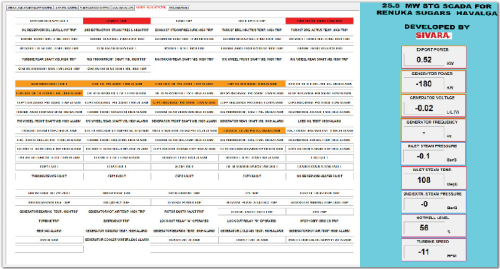

Supervising Steam Turbine Operation

Power Engineering

Shree Renuka Sugars

India

SCADA/HMI

Comprehensive monitoring and control of a steam turbine operation, along with troubleshooting its health via trends, alerts and predictive models. HMI for monitoring the process parameters and automating the steam generator operation.

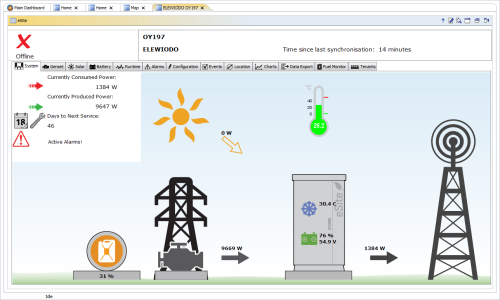

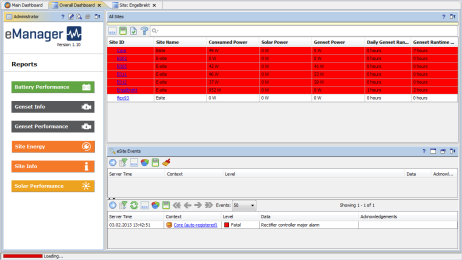

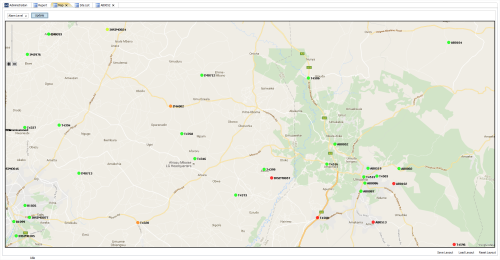

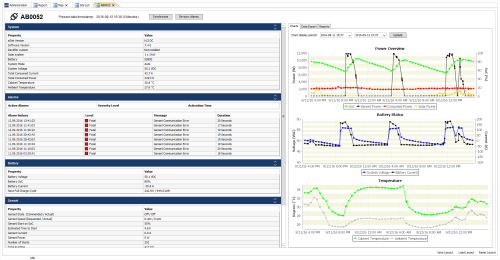

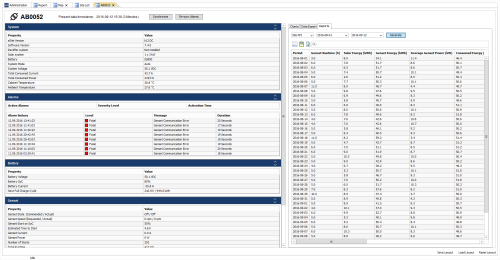

Monitoring of Telecom Tower Energy Supply

Telecom Operators

Flexenclosure

Sweden

SCADA/HMI

AggreGate SCADA/HMI-based reference solution for managing the power systems of base cellular stations. A number of installations within the international communications networks (Airtel, Telenor, Etisalat, and others).

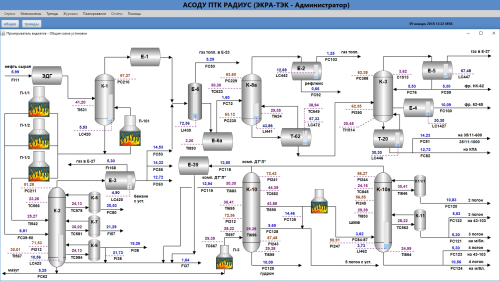

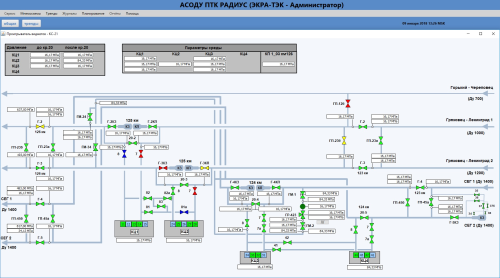

Supervisory Control for Oil and Gas Transportation

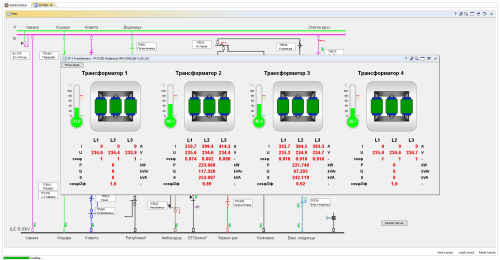

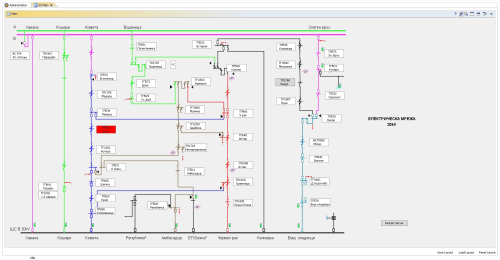

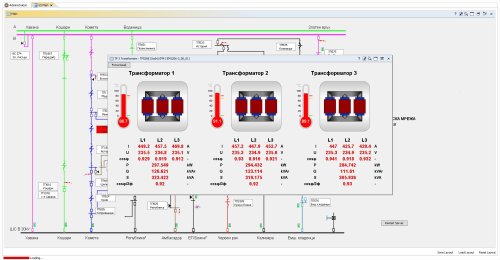

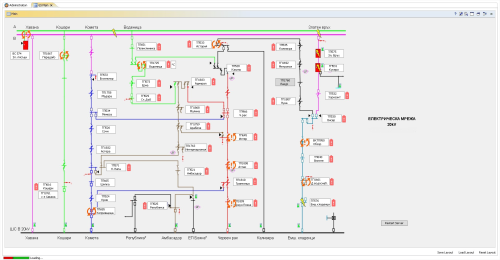

Electrical Transformer Monitoring

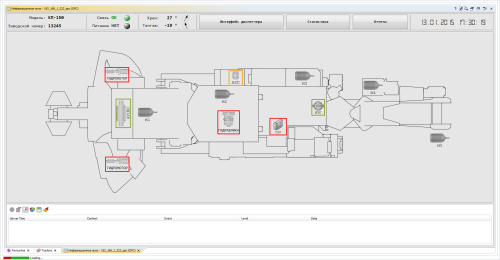

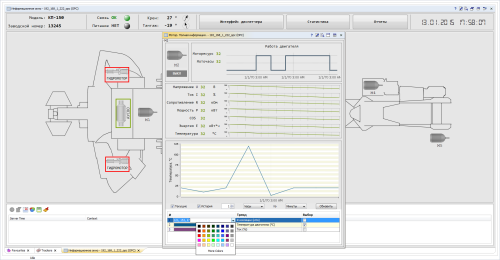

Road Heading Machine Supervision

Transportation and Logistics

Ilma

Russia

SCADA/HMI

Road heading equipment monitoring and management product. Works with the Genesis OPC DA server, with an average of 250 tags per unit, up to 10 units at a mining facility.

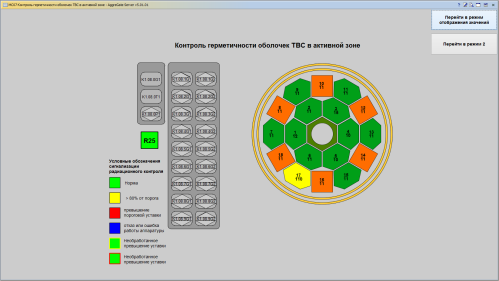

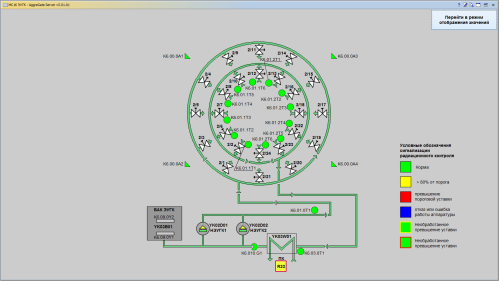

Real-Time Data Acquisition System for a Nuclear Research Reactor

Power Engineering

St.-Petersburg Nuclear Physics Institute

Russia

SCADA/HMI

Comprehensive monitoring starting with the reactor neutron parameters up to the facility radiation levels. 200 000 signals per second collected from the National Instruments chassis and stored. Real-time oscillograms and a total of 100+ HMIs, four failover servers.

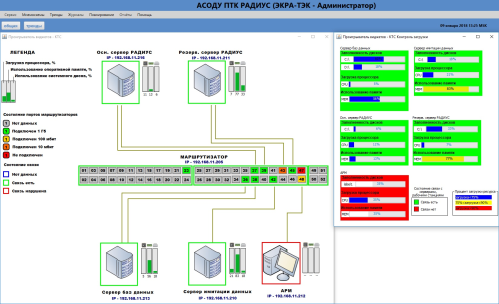

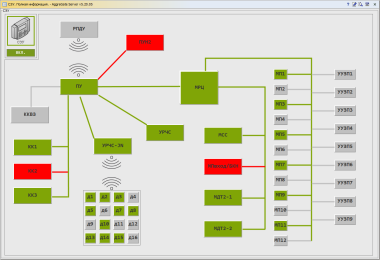

Groundbreaking Architecture

Unlike traditional SCADA systems, AggreGate SCADA/HMI has no difference between the development and runtime environments. The system server, optionally backed up by the second failover server or connected into a multi-server distributed installation, runs a single "project".

It communicates with controllers, stores the trend data in an SQL database and serves remote connections from the operator workstations, HMI touchscreens and third-party systems. System administrators have no reason to physically access the server, even the most complex administrative operations are performed remotely via a secure network connection.

Moreover, the same server can share modules and functions with other solutions, such as SoftPLC, MES, BI, EAM or ITSM.

Wide Industry Coverage

Organizations in all industries use the AggreGate family products every day to streamline IT operations, reduce costs and automate their businesses.

Integrating Automation with IT

While the supervisory process control is a key task for automation and maintenance engineers, the overall efficiency of any industrial company is heavily dependent on the health of its IT infrastructure. Most SCADA systems are now integrated into a corporate IT infrastructure by operating through the IP network, using common SQL databases for storage and authenticating users through Active Directory/LDAP.

However, there are no industrial automation systems that are equally aware of how to manage an IT infrastructure. This domain includes thousands of dedicated tasks, from the traffic decomposition helping find the bandwidth bottlenecks up to monitoring the VoIP communications health.

The situation becomes totally different with AggreGate. The AggreGate IoT Platform serves as a common foundation for both AggreGate SCADA/HMI and AggreGate Network Manager, an enterprise-grade IT infrastructure management solution designed for corporate networks, telecom providers and data center operators.

The Network Manager is not just integrated with SCADA/HMI. Two systems share the same core, making it possible to have no difference between PLCs, routers/switches and monitored applications/services. Both products share all data acquisition, storage and processing subsystems, as well as alerting, reporting, modeling, visualization, and other functionality.

This ensures unparalleled interaction between industrial and IT engineers, as well as a single point of northbound integration into EAM/ERP/ITSM and other Business Intelligence systems. The process downtime and performance/quality degradations are equally caused by the automation and IT infrastructures, so having an umbrella monitoring system for both provides a single point of control for the company management.