Key Features of MES/OEE

- A flexible platform for building MES tailored to continuous, discrete, or recipe-based manufacturing processes

- Implement ISA 95 processes that align with the established practices of your enterprise, moving beyond theoretical guidelines

- Utilize the class module to model and represent unique, company-specific business objects and their interactions, such as batches and work orders

- Configure the planning module to reflect the actual enterprise workflow

- Ensure seamless architectural integration with SCADA systems for improved supervisory control

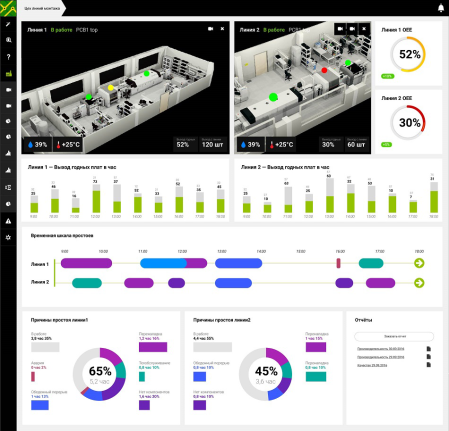

- Monitor and optimize downtime and efficiency across production lines, individual plants, and operators, focusing on specific products

Key Features

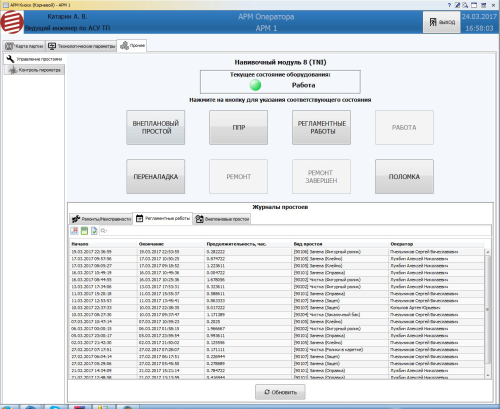

Downtime management

- Align with the internal calendar for scheduled downtime

- Receive repair data from ERP and/or external MRO systems

- Monitor and record unplanned downtime events

- Generate reports on process quality statistics

- Automatically block alarms at SCADA and Edge levels during planned downtime

- Fully implement MRO processes on the MES side if necessary

Overall Equipment Effectiveness (OEE)

- Conduct in-depth assessments of Overall Equipment Effectiveness for processes, installations, production lines, and overall production systems

- Generate detailed reports on OEE metrics, segmented by product and operator, to identify performance trends

- Evaluate the influence of the six major loss factors on OEE performance indicators

- Provide assistance in configuring production lines to meet and exceed planned performance targets

- Populate ERP and EAM systems with real-time, accurate production data to enhance decision-making

- Achieve reduced operational costs and enhanced efficiency across production processes

Production planning

- Adapt to discrete and recipe-based production planning with high flexibility

- Develop a complete model of production processes on the MES side, maintaining master data across EAM/ERP and SCADA levels

- Utilize low-code configurations to seamlessly integrate with various protocols, achieving specific goals without traditional programming

- Produce reports detailing process quality statistics

- Display production schedules dynamically using Gantt charts

- Implement planning through multi-agent management, allowing virtual agents to place and fulfill orders

Labeling and tracking

- Direct connection of scanning points using RFID, QR codes, and other technologies

- Maintain a database to track components, raw materials, by-products, and finished goods through production

- Use graphs, diagrams, and tables for flexible data visualization

- Link tracking points to digital twins of installations, production lines, storage facilities, etc.

- Low-code integration with supply chain and distribution systems (both EAM/ERP-based and custom-built)

Batch and Recipe Management

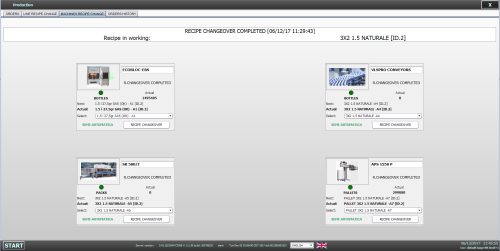

- Implement batch and recipe management on a single HMI/SCADA/MES platform without complex integration chains

- Use the Classes module and a relational DBMS for flexible batch management, adding attributes and connections within the production model

- Utilize the Models, module for recipe management, directly applying settings to controllers and equipment at the dispatching level on the AggreGate platform

- Ensure correct automatic equipment reconfiguration when applying a recipe at the MES level

Statistical Process Control

- Implement flexible configurations for Statistical Process Control (SPC) and Advanced Process Control (APC)

- Utilize dozens of chart types and thousands of settings to create production-specific dynamic dashboards

- Combine internal MES data, AggreGate SCADA/HMI data, third-party SCADA systems data, direct PLC data streams, and EAM/ERP data

- Apply both simple statistical analysis and advanced machine learning and anomaly detection algorithm

Business process management

- Implementation of BPM functionality based on the Workflows

- Visual process development in a dedicated editor

- Combine backend production model logic with frontend operator interaction logic in a single process

- Use universal operator interaction elements for rapid process setup

- Implement MES-side processes typical for EAM and ERP systems, including a data model

- Set up a document repository and master data system, linking documents to production models and business process steps

Vertically integrated MES

- Implement a complete stack of production automation with AggreGate as a vertically integrated production management platform

- Achieve technological compliance with leading global industrial platforms

- Deploy the dispatching level using AggreGate SCADA/HMI and Edge/SoftPLC technologies based on AggreGate Edge

- Acquire data from other SCADA systems or directly from instrumentation using any industrial protocol

- Implementation of a wide array of EAM and ERP system tasks based on AggreGate

Completed projects

System integrators and engineering firms worldwide use AggreGate in their production management system projects. View real-life examples below or visit Clients page for a comprehensive project list.

Smart Line Development

Manufacturing

Ostec

Russia

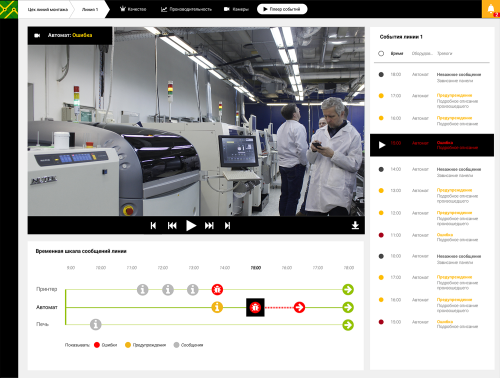

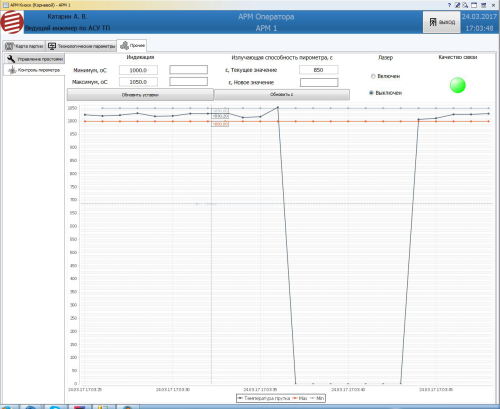

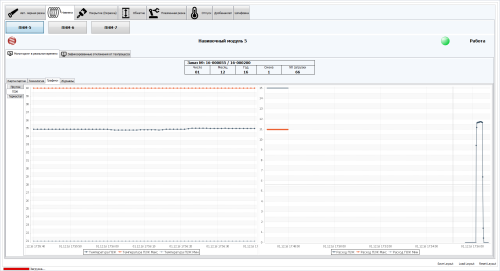

SCADA/HMI

Electronic module production enhancement. Technological process supervisory control and production defect analysis system deployed on the surface-mount transfer line. The system provides the production control and manufacturing deviation notifications. It also assists engineers both in the production process arrangement and product analysis for the effective corrective actions.

SCADA and MES for Spring Manufacturing

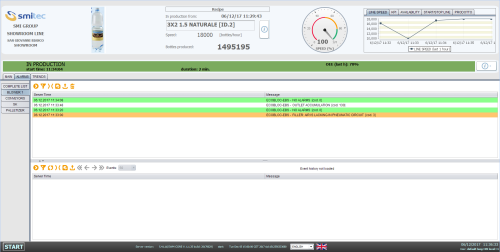

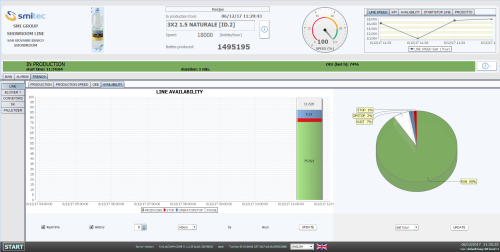

Packaging Line Management

Manufacturing

SMI Group

Italy

SCADA/HMI

SMITEC SWM is a modular and configurable IT and Industry 4.0 solution based on AggreGate SCADA/HMI for packaging (or more general manufacturing) line supervision: monitoring, data collection, production tracking, production execution and performance KPI calculation (OEE).